The Graphene, which has won the Nobel Prize and is called the “dream material”, is the simplest and thinnest material mankind has ever discovered, lighter than wood yet stronger than diamonds. The state of the art graphene, with a two dimensional structure in which carbon atoms are arranged in a plane, has an electrical conductivity of 100 times greater than copper and it is 200 times stronger than steel.

It has a tensile strength that is 200 times stronger than steel at 1020 Gpa and it is about twice as strong as diamond with a hardness of 10.

It has a conductivity of more than 100 times greater than copper and a thermal conductivity of more than twice as high as diamond.

Carbon atoms have a plane of honeycomb structure that can be bent or wheeled and maintain their performance even when folded and unfolded.

High in physical and chemical stability and transparent as glass by having light penetration of 99%.

Nano carbon developed by WIN&WIN absorbs vibration more efficiently than normal carbon and reduces shock and vibration faster so it is not transfered to the rider and bike. Fundamentally it makes riding a lot more stable.

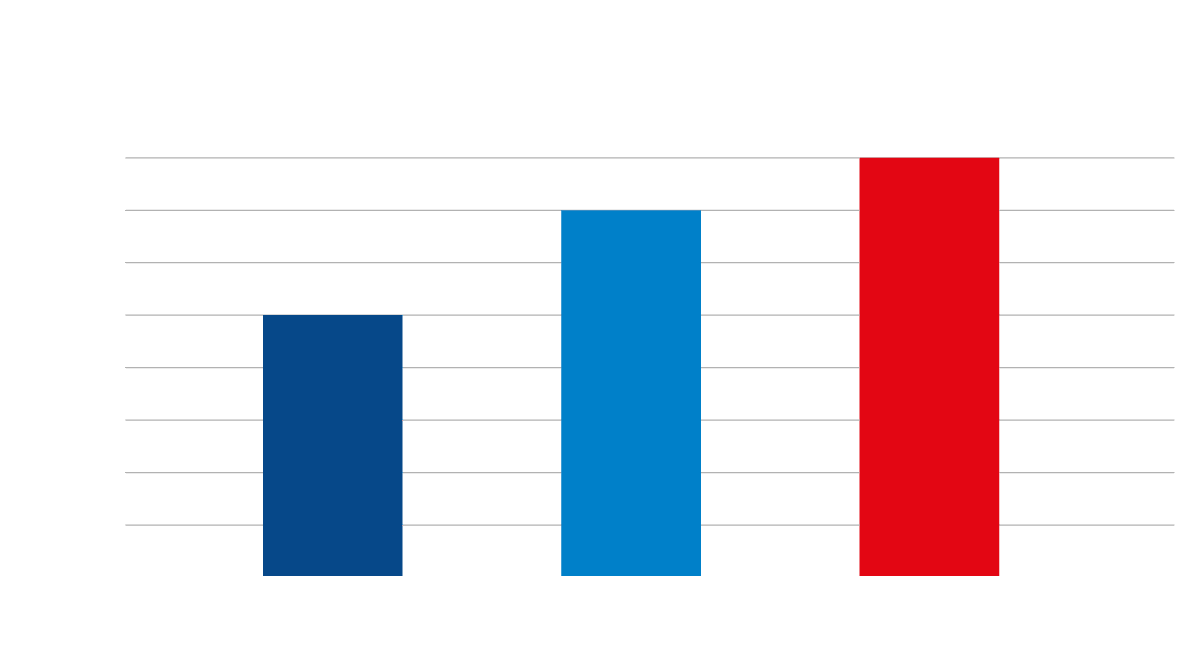

While normal carbon prepreg stands 250,000 times at durability test, Nano carbon prepreg stands 380,000 times. It proves Nano carbon frame is excellent on durability over 40% greater than a normal carbon frame.

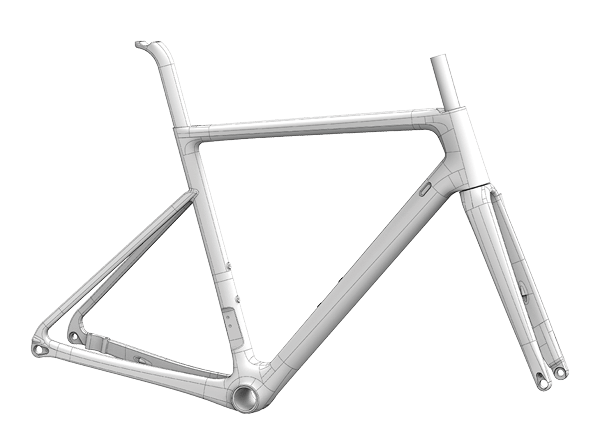

WIAWIS bike frame is made of high modulus nano carbon which has proven its superior properties at Recurve Olympic Archery.

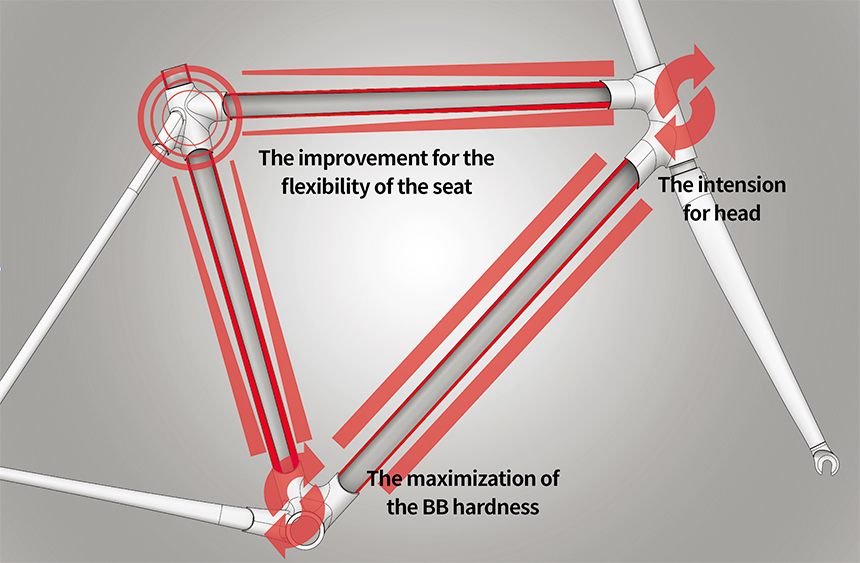

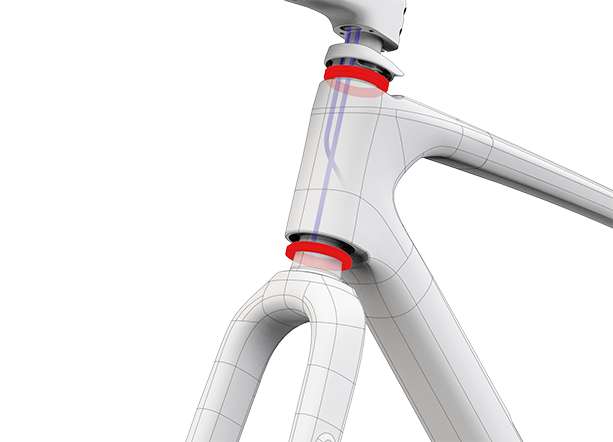

WIAWIS Head tube was gradually tapered from 1-1/8" to 1-1/4" for road bike and 1-1/8" to 1-1/2" for mountain bike to increase rigidity and stability. It improves accuracy and reactivity of steering in riding.

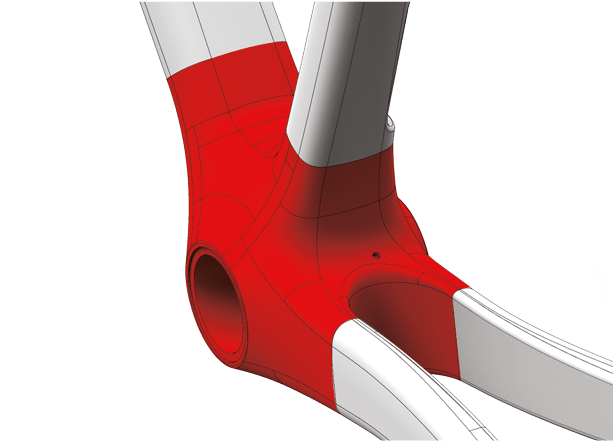

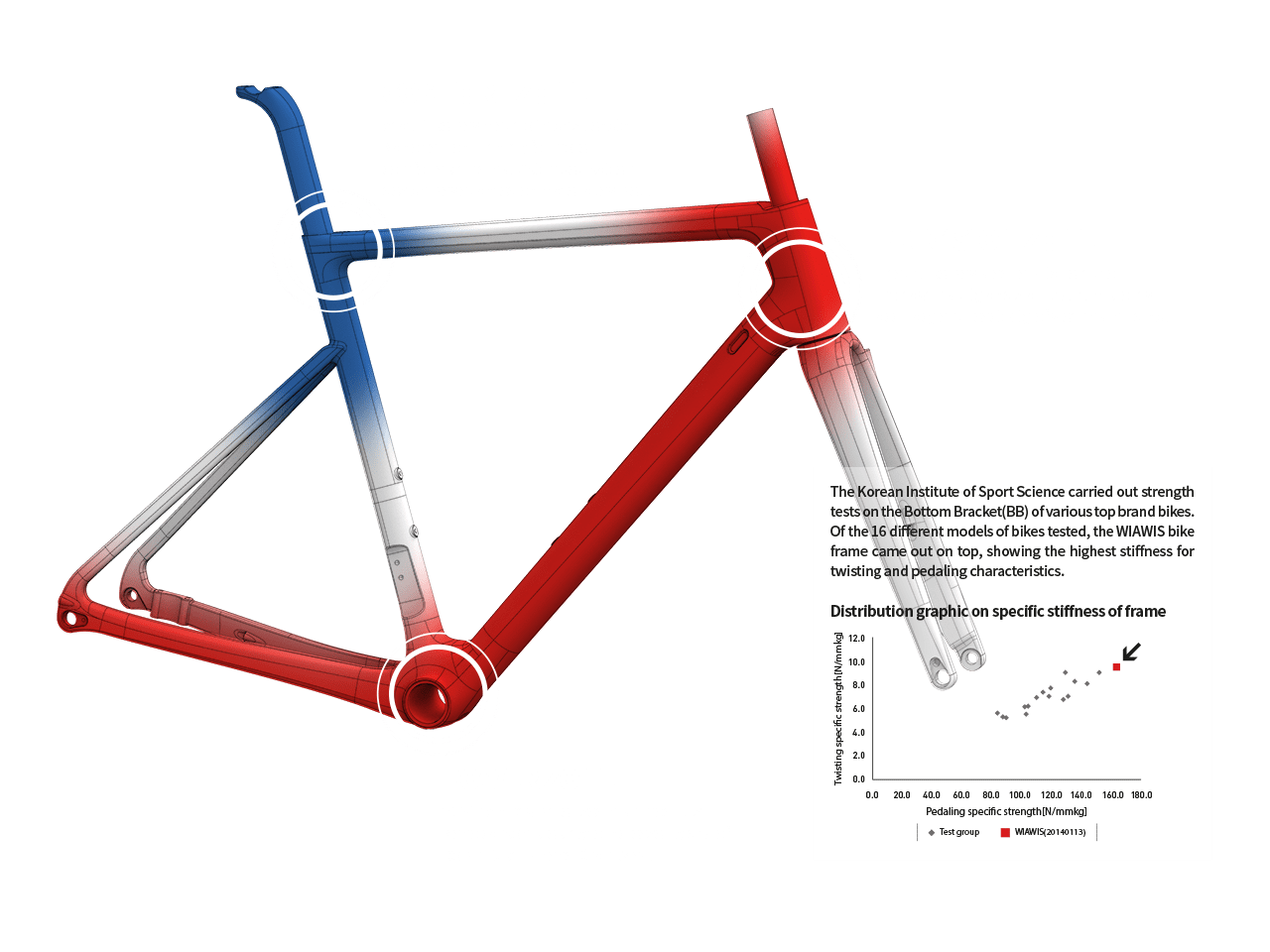

More widely designed BB increase stiffness of frame and transfers pedaling power more efficiently. It gives higher velocity and reduces unnecessary twisting of frame, which provides improved handling performance when riding.

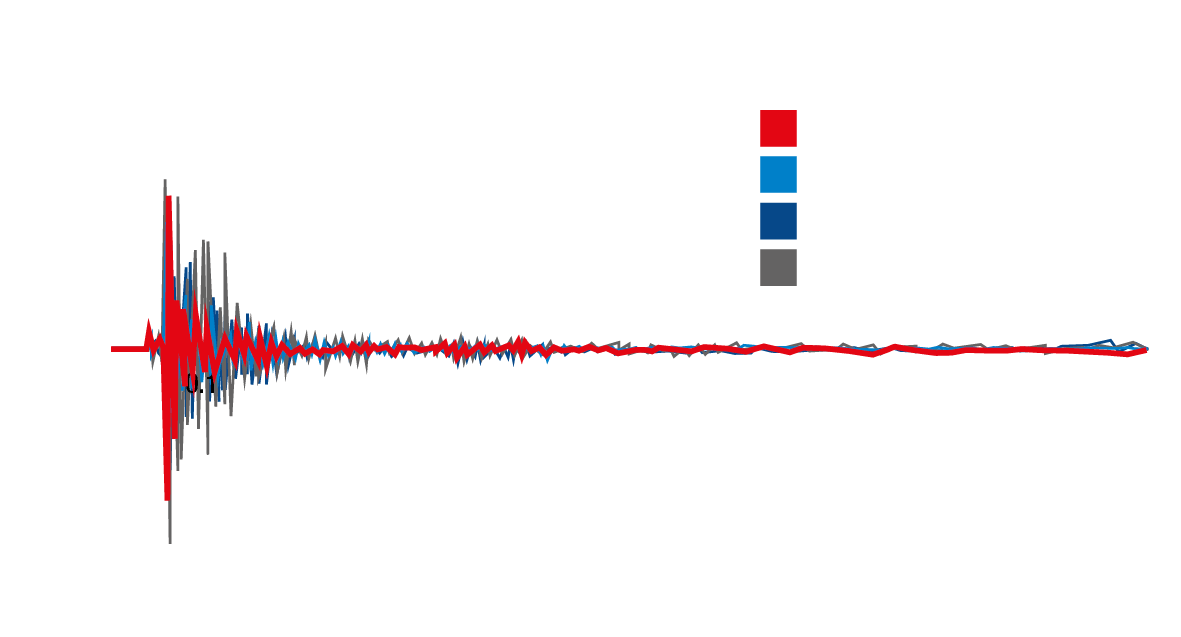

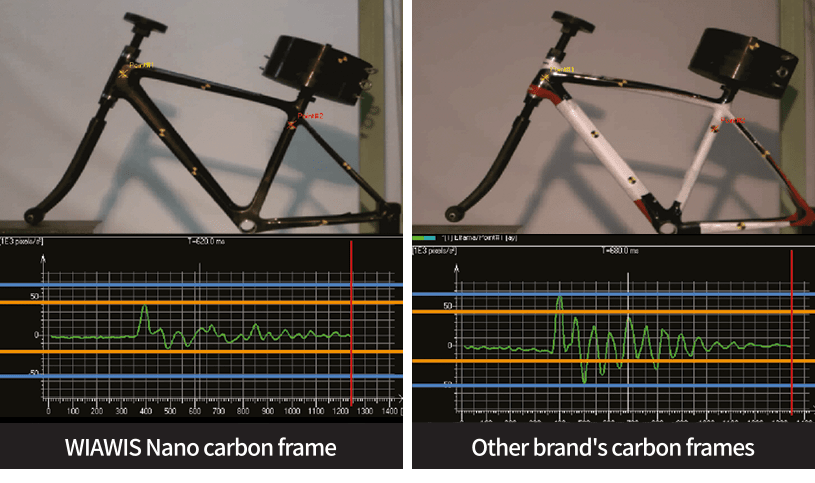

Graphs on the left show impact velocity of point#1 movement. The less movement, the better impact absorption is. It means it will absorb vibration faster, so the period of vibration is shorter. WIAWIS Nano carbon frame is better than the normal carbon frame more than 50% at absorbing impact and reduction vibration.

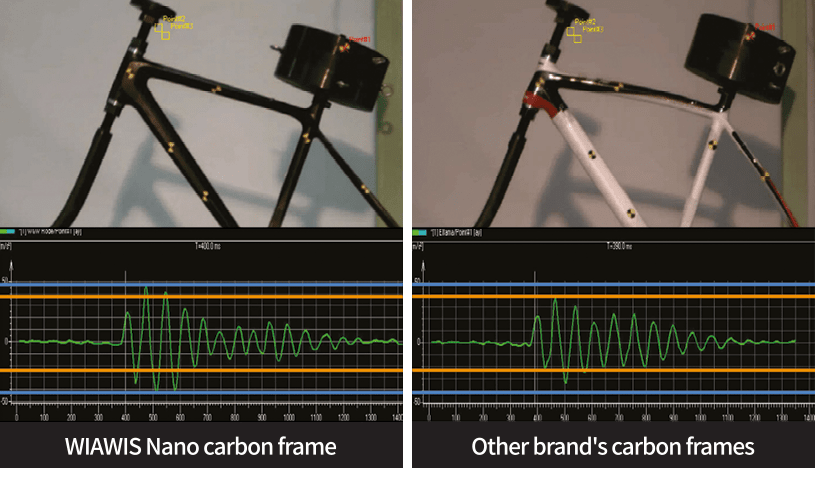

More flexibility of the seat tube provides better comfortable riding. In addition, more flexibility of seat stay helps moving seat tube ore smoothly. Graphs on the left show the vibration width and period of 'Point2' and we can see WIAWIS Nano carbon frame moves more flexible with wider vibration period than other brand's.

The performance of a Bike frame can be decided on how efficient the rider can transmit his/her power into the pedals and then how efficient that power can be converted into kinetic energy. The main power Zone of the Bike frame is around the bottom bracket (BB) and Chain Stay. The Riders points of contact with the Bike are feet, hands and bottom, and To be most efficient at these 3 points, these 3 points need to be resistant to twisting. The more twist the more loss of energy being transmitted into the Bike.

Elements such as impact resistance, vibration absorption and flexibility of Seat tube directly affect the ride feeling. When the frame absorbs shock and vibration the rider feels less hard impact through the Bike wheels and this will give the rider the feeling of less fatigue during long riding. In addition, the more flexible the Seat tube is, the less fatigue a rider feels through his body core.

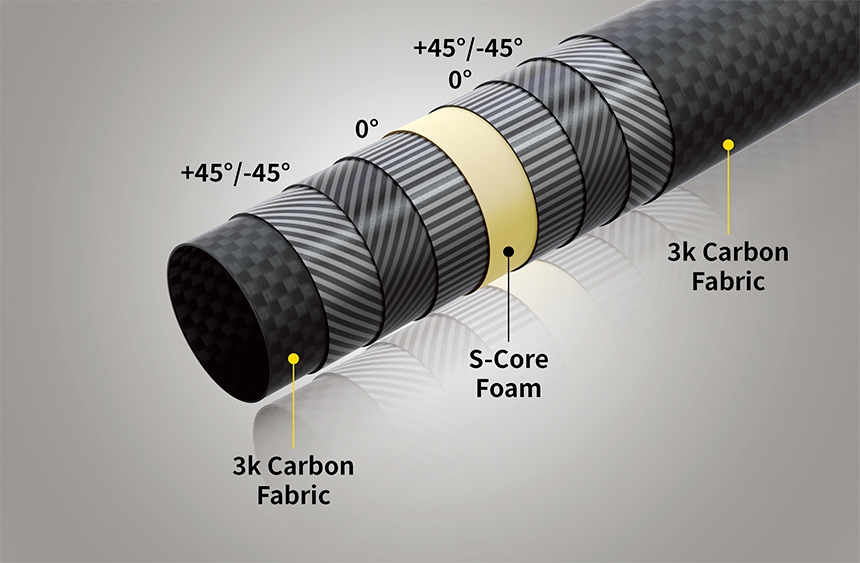

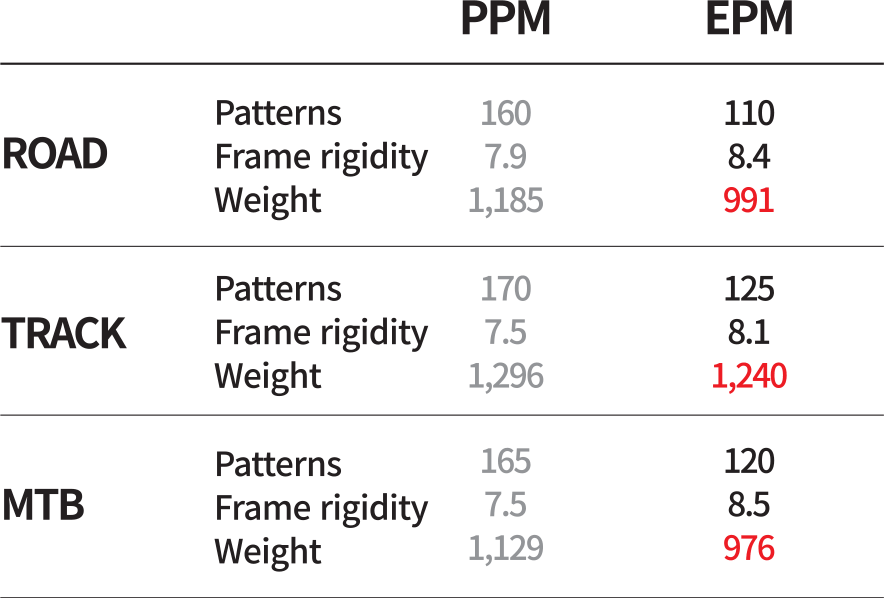

Bicycles must vary in material thickness and pattern for each part of the frame, depending on the performance required by each product for road, mountain and track.

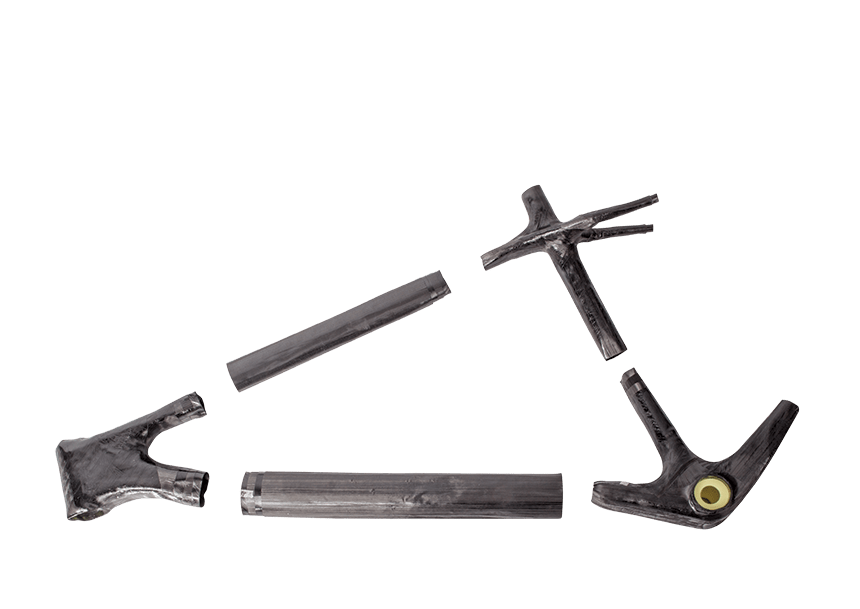

1. The layup area is divided into several parts

2. Many cuts and connections

(Head tube, Top tube, Down tube)

3. A nylon plastic tube is placed inside the frame and air is pumped to form

1. Added rigidity ofthe product with integral molding

2. Lighter weight

3. Increased efficiency and durability

4. Due to reduced cuts and connections

Coated rubber acts as a balloon

inside the mold, inflating and forming

For prototypes manufactured using the EPM method, frame rigidity test resulted in approximately 6 to 8% improvement in frame rigidity compared to PPM method and weight reduced by more than 10%.

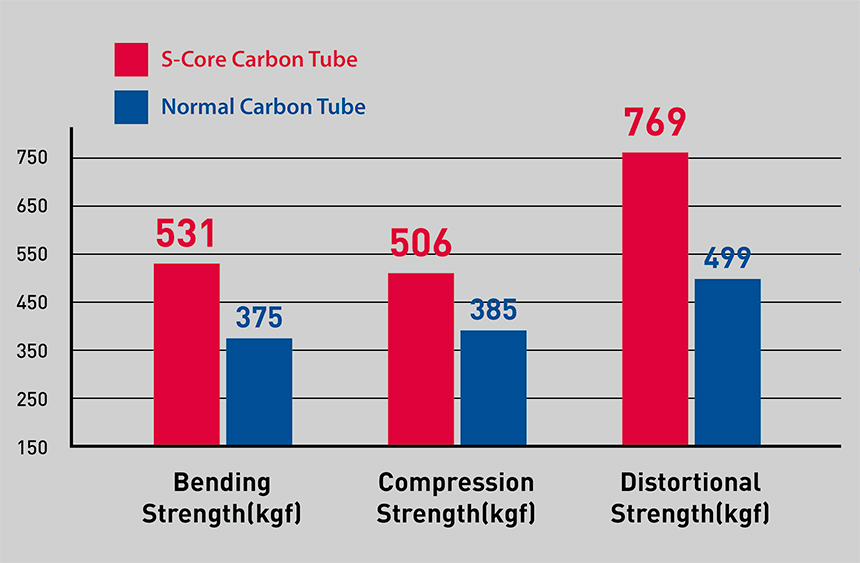

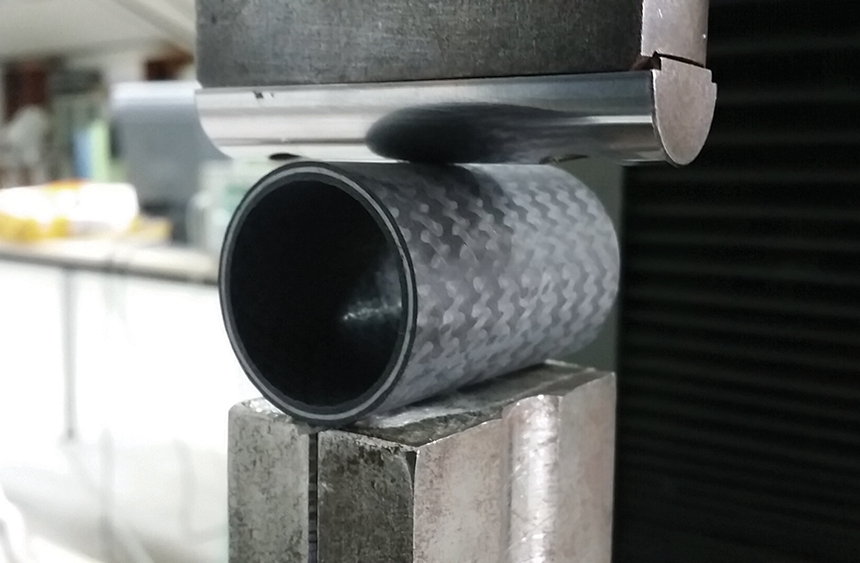

Proven Strength Nano Carbon Has Been Applied To The Frame And Patent- ed Taper Structure With S-Core Foam Shaft Gives More Powerful And Stable Driving.